Types of wear

There are two primary types of wear that affect mining equipment, both with distinct characteristics and contributing factors.

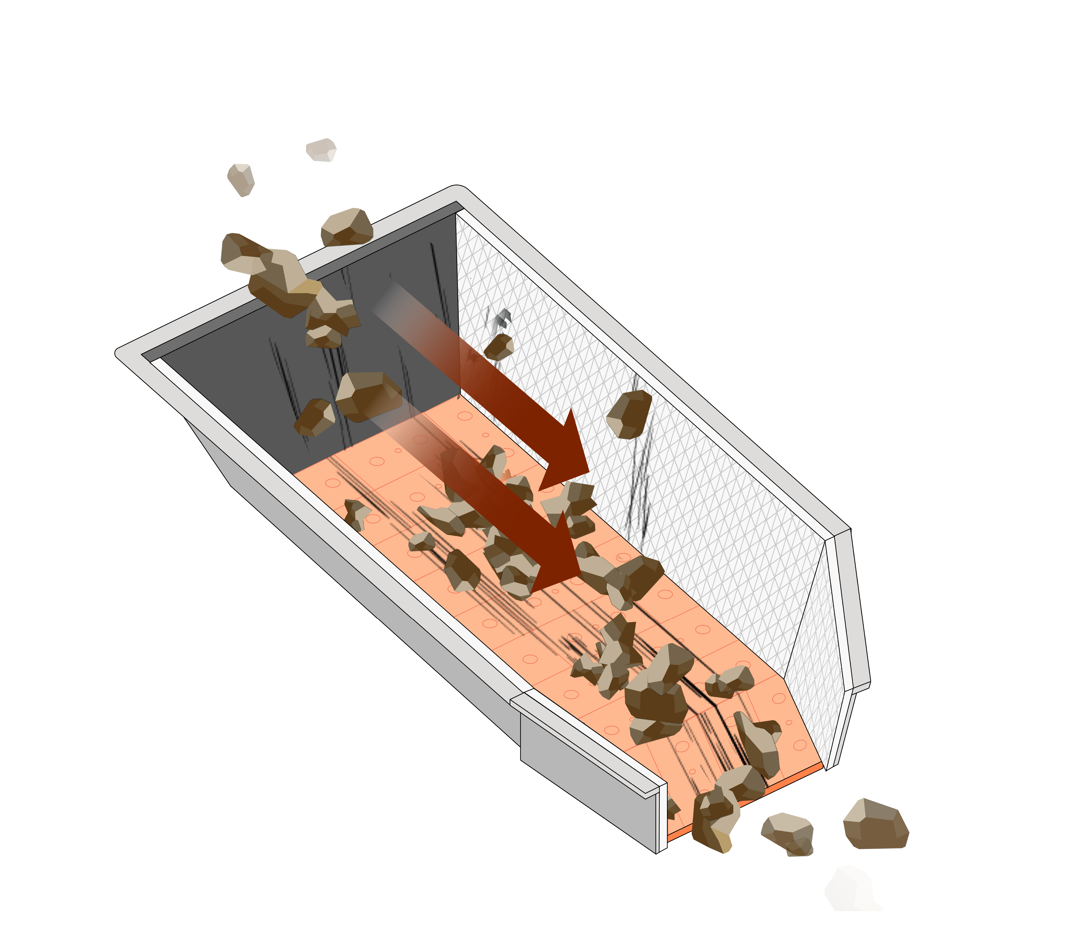

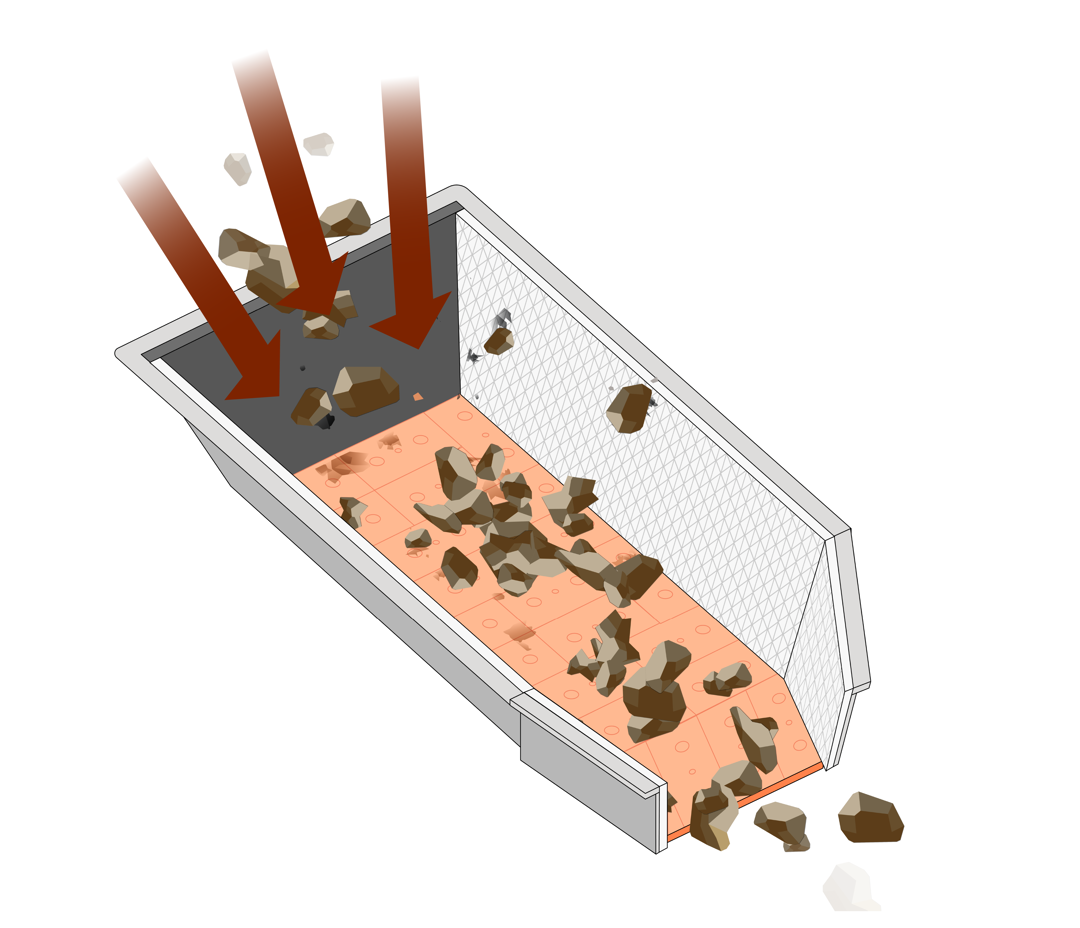

Impact wear

Impact wear results from collisions between solid bodies, when at least some of the forces are applied perpendicular to the plane of contact. This is common in equipment that handles heavy and irregularly shaped rocks, like hoppers and chutes. The repeated impacts lead to deformation and fracture, causing significant material loss and reduced equipment lifespan.

Abrasive wear

Abrasive wear occurs when hard particles or protuberances forcefully move along a solid surface, causing material removal. This is prevalent in mining due to the presence of abrasive materials like sand, dust, and rock particles. Sliding wear – a type of abrasive wear in which material is lost from friction between two solids – is especially common. Equipment such as crushers, mills, and conveyor systems frequently encounter this type of wear.