Solutions to prevent wear

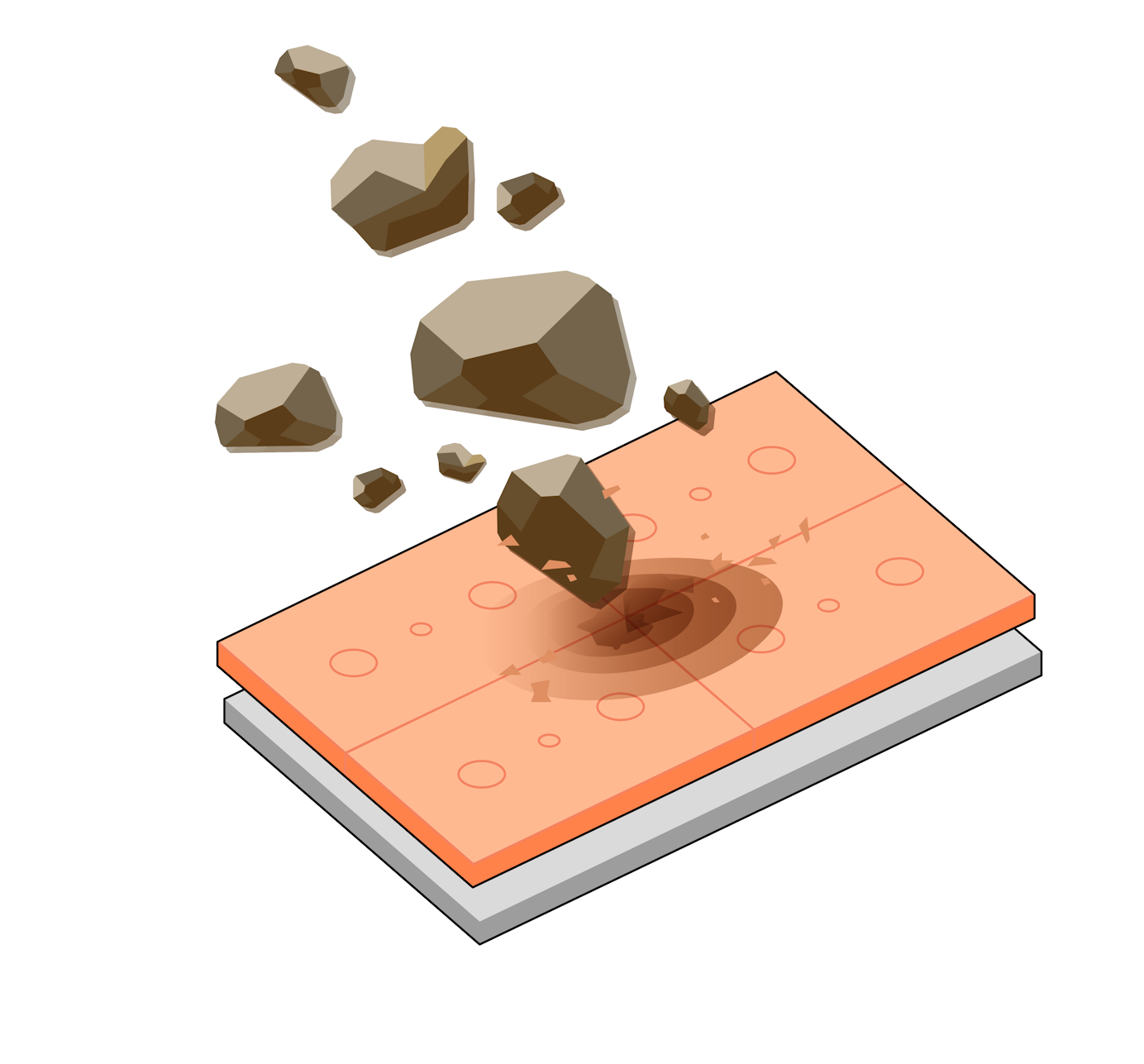

Wear protection plates act as sacrificial layers of wear-resistant surfaces in mining operations.

These plates are typically made from materials such as steel, rubber, ceramics, polyurethane, or composites (a combination of these materials).

These plates are designed to protect equipment from wear and damage, ensuring optimal efficiency and the highest availability of the equipment.

By utilizing wear protection in mineral mining equipment, wear losses could potentially be reduced by 15% in the short term (10 years) and by 30% in the long term (20 years).

In the short term, this would equate to worldwide savings of €31.1 billion, 280 TWh of energy and 145 million tonnes of CO2 every year. In the long term, the annual benefits would be €62.2 billion, 550 TWh of energy and 290 million tonnes of CO2.*

Wear protection plates are highly effective in protecting processing equipment (crushers, screens and feeders, for example), handling systems (like trucks, chutes and hoppers), and at transfer points.

However, wear is affected by many different parameters so it can be difficult to find the correct wear protection solution for a specific mining operation.

The next section of the Knowledge Hub will look into this and outline the basics of how to choose the right option for protecting your plant.

*See Kenneth Holmberg, Päivi Kivikytö-Reponen, Pirita Härkisaari, Kati Valtonen, Ali Erdemir, ‘Global energy consumption due to friction and wear in the mining industry.’ Tribology International 2017, 116-139