Tough wear protection

To be successful, this type of wear protection must be harder than the materials it is exposed to. The basic principle is, the harder the better.

However, as the surface hardness increases, these materials typically become brittle, and more prone to cracks. This means that users need to base their choice of material on the application criteria.

For applications with low levels of impact energy, it’s quite straightforward and the decision is largely about weighing up cost against wear life.

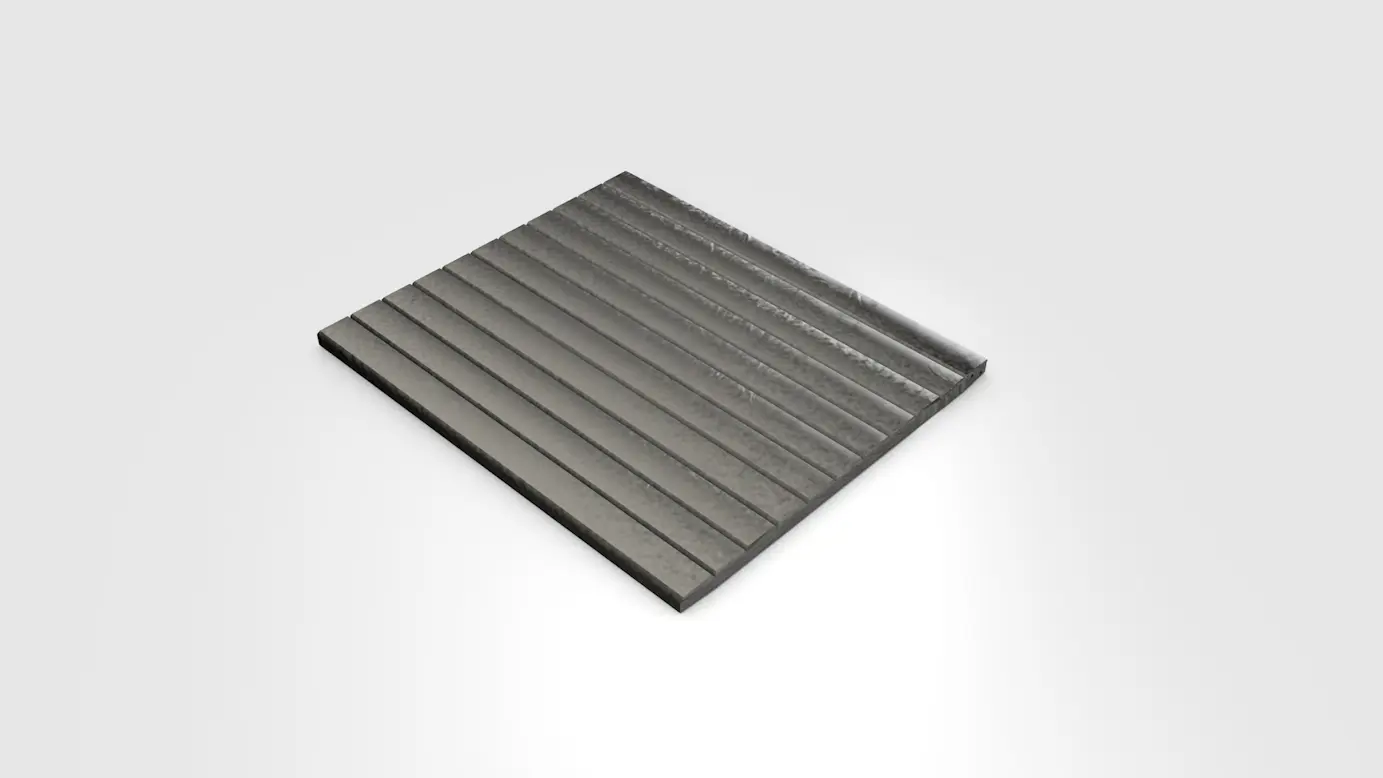

Photo: Hardfacing Plate

Photo: White Iron Plate

Photo: White Iron Plate

However, if applications are more complex, involving high levels of both impact energy and abrasion, then these types of materials quickly start to show their limitations.