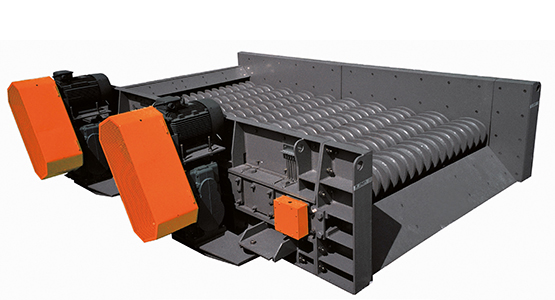

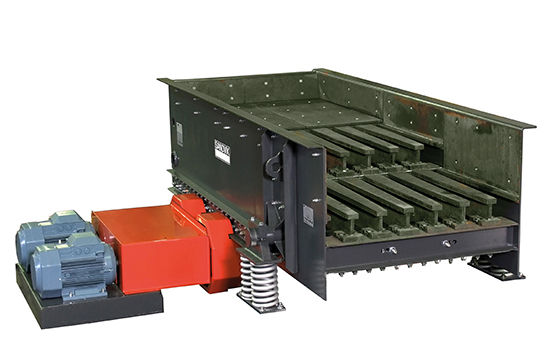

Horizontal screen, linear stroke

In comparison with inclined screens, horizontal screens generally provide greater accuracy and capacity, and require less headroom. The decks operate at a relatively flat angle of less than 10°. Sometimes they can even be set up with a negative incline, so that the feed end is actually lower than the discharge end.

Rather than relying on gravity, the feed is propelled forward by the linear (or sometimes elliptical) motion of the screen. The feed, thus, stays on the screen for a longer time than it would in an inclined screen of the same size. As a result, material has more opportunities to fall through the apertures, and more effective screening can take place. This makes horizontal screens especially useful for secondary screening and final sizing. Another reason for chosing horizontal screens is the lower installation height.

There are some drawbacks to using a horizontal screen, however. The relative complexity of the mechanism drive system means that these screens are often more expensive, and they may require more maintenance than simpler apparatus.